SWEPCO 121 Tri-Plex Universal Grease

Price on request

- Description

- Additional information

- Properties

- Benefits

- Markets

- Applications

- Technical Details

Description

SWEPCO 121 Tri-Plex Universal Grease is a multi-service grease that provides superior resistance to heat, shock, water and extreme pressure in a wide range of applications. It makes bearings run longer, cooler, smoother, quieter and more efficiently and increases both bearing life and equipment reliability.

WITH PROPRIETARY TRI-PLEX CHEMISTRY SWEPCO 121 Tri-Plex Universal Grease is a high performance grease based upon SWEPCO’s new, proprietary Tri-Plex chemistry … an important advancement that produces a tighter molecular structure. This improvement and special polymer modification enhance a wide range of performance properties, including … resistance to shearing, shock, high temperature oxidation, bleeding and water wash out.

Combine enhanced performance in these critical areas with SWEPCO’s advanced EP performance, rust and corrosion protection and with SWEPCO 121 Tri-Plex Universal Grease you have a new class of multi-service grease which lasts significantly longer and provides superior lubrication in the broadest possible range of applications.

For some examples of SWEPCO 121 Tri-Plex Universal Grease click this link to read the case studies of Goodyear Nederland B.V. Tilburg, Jansma Drachten and Garage Trias Heemstede.

Additional information

| Brand | SWEPCO |

|---|---|

| NLGI | NLGI 1, NLGI 2 |

| Shipping | Case of 10 grease cartridges, Case of 30 grease cartridges, Drum (186 kg./208 liter), Keg (54 kg./60 liter), Pail (16 kg./19 liter) |

- Proprietary tri-plex chemistry and high performance polymers;

- Wide temperature range of -40° to 450°F intermittent (-40°C to 268°C);

- Unmatched shear stability for longer working life;

- Exceptional shock resistance;

- Highly resistant to high temperature bleeding and oxidation;

- Excellent low temperature pumpability;

- Wont wash or spray off;

- Lowers bearing temperatures; reduces vibration;

- Superior EP performance;

- Environmentally responsible;

- For all types of bearings and grease points.

- One grease for all applications eliminates the need to stock multiple greases;

- Extends bearing life;

- Reduced grease consumption;

- Less grease related downtime;

- Offers superior shear stability.

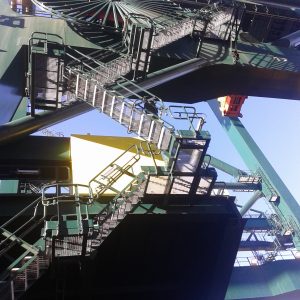

- Heavy Construction;

- Manufacturing;

- Mining;

- Transportation.

- Bearings of all types ball, roller, tapered, thrust, needle, ball, screw;

- Journal bearings, bushings, slideways and spherical bearings;

- Greased gearing, chassis, king pins, u-joints, disc brake calipers, fifth wheels, trailer wheel bearings, couplings;

- General manufacturing up to 375°F (190°C) continuous and 450°F (232°C) intermittent;

- Centralized lube systems;

- Low temperature applications as low as 40°F (-40°C).

Would you like to receive more information about this product? Please contact us at info@stratson.nl.

We can send you per e-mail, for example:

Case studies,

Technical Data sheets &

Material Safety Data Sheets.

Let us know by email what information you wish to receive.