Changing Lubricants on Open Gears

All open gears need lubrication to operate properly and prevent damage to the gear teeth. These gear sets are found on ball mills, rod mills, grinders, draglines, power shovels, and crushers. There is usually a bull gear with 1 or more pinion gears that drive the larger bull gear.

One of the objections that come up when changing to SWEPCO lubricants is cleaning the old lubricant off the gear sets. Many open lubricants are asphaltic based that build up on the gears, requiring many man-hours to clean.

This Tech-i-Gram is going to focus upon equipment that has an automatic lubrication system and will be switching to SWEPCO 222 Sprayable EP Open Gear Lube.

The critical parts of this procedure are: 1) Inspection, 2) Change out, and 3) Follow Up. It is important to follow each of these steps and do not take any short cuts. During the inspection phase you will need to physically check to make sure all the equipment and lubricating system is working properly. Any mechanical issues need to be addressed prior to the change out, failure to do so will be a waste of time and if equipment failure occurs during or after the change, our lubricant will be blamed. It is important to monitor the conditions during the change out period to catch any problems before they become an issue. The follow up will provide you with before and after data to present to your customer. Please read all the instructions carefully prior to starting.

Procedure of changing lubricants on open gears:

- Inspect both the pinion and bull gears for wear, alignment, and build-up of lubricant. It’s recommended to take pictures with a strobe light to document the before conditions.

- Inspect the lubricant delivery system for worn or cracked hoses. Check the pump and timer to make sure they are working properly.

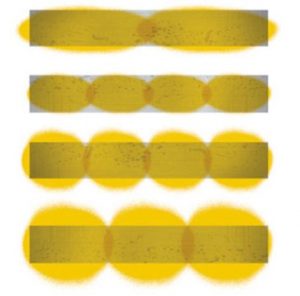

- Using a piece of cardboard, obtain the spray pattern of the product being used to check nozzles for alignment and any spraying issues, (i.e. clogging, low air pressure, etc.)

Correct spray patterns on gear teeth flanks.

Correct spray patterns on gear teeth flanks. - If the gear has a shroud, check to make sure the drain in the bottom is not clogged.

- Record temperature readings across the face of the bull gear. Retain these readings and all inspection data for your final report.

- Replace the current lubricant with a drum of SWEPCO 201 or 203 ISO 680 Multipurpose Gear Lube, use the ISO 1000 for heavily loaded systems. The 201/203 gear lube is fortified enough to protect the gears and will clean up the delivery system and the gears. Depending upon the amount of build-up, this step may take 24 hours or more to remove all the old lubricant. It is important to record temperature readings during the process and check to make sure the spray nozzles are not clogged and operating properly. If the gears are clean, you can skip this step.

- Replace the drum of gear oil or previous lubricant with SWEPCO 222 Sprayable EP Open Gear Lube. Record temperature readings and check the spray pattern to make sure everything is operating properly. Take pictures of the spray pattern to add to your report.

- It is recommended that for the next two weeks you continue to take temperature readings every few days and make sure the shroud drain is not clogged from the cleaning process. By monitoring the temperature, you can start to cut back on the amount or frequency of the lubricant sprayed on the gears. Check the OEM recommendations of the amount of lubricant to be applied. In many cases, due to poor lubricant performance, customers will flood the gears with lubricant in hopes of reducing wear. When lubricants are over applied, they create problems such as excess heat, build-up of lubricant at the root of the gear, and clogging of the drain. A drain clog can cause misalignment of the pinion gear.

- For the first six months take temperature readings and check the spray nozzles every two weeks.

- We can assist you in setting up a service report showing temperatures, spray patterns, and pictures taken before and after the conversion. On-site personnel will have to record temperatures, take pictures, and do the inspections.

Using a high-quality lubricant at the correct amount will save you money, housekeeping expenses, and unexpected down time. This procedure may be used on most ball mills, rod mills, and other open gear applications. Changing Lubricants on Open Gears is not complex as long as this procedure is followed. Bottom line, the changeover will save you both time and money.

“to keep it running…!”

For more information and assistance, please contact us.

Source: SWEPCO®