INDUSTRIAL GEARS

Industrial gears are used everywhere to change speed, direction, and torque of a drive from a power source such as electric motors or engines. Gears have been used since the 1500’s and originally made of wood and lubricated with animal fat.

In the 1700’s iron was introduced which allowed the gearboxes to handle greater loads with significant reduction in size and weight. That trend continues today. A gear box made today is one-third the weight and size of one made in the 1950’s. Most of the teeth today are case hardened to provide a strong, extremely hard, wear resistant tooth. The gear design must be matched to the purpose desired. Increasing or decreasing the speed, torque, or direction may require a different gear tooth design depending upon load, speed, temperature, space, cost, noise, and environmental requirements.

Lubricants play a vital role in the operation, life, and gear performance of a gear box. Gear lubricants protect gears from damage by:

- Heat dissipation.

- Clearing away contaminates or wear particles.

- Preventing varnish or carbon deposits.

- Keeps oxidation and degradation products in solution.

- Lubricates seals and bearings.

- Deliver performance and Extreme Pressure additives to metal surfaces.

Types of industrial gears

Spur Gears |

Helical Gears |

Herringbone Gears |

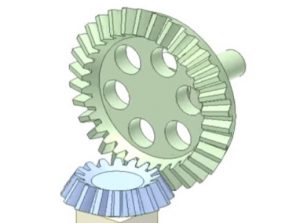

Straight Bevel Gears |

Spiral Bevel Gears |

Rack and Pinion Gears |

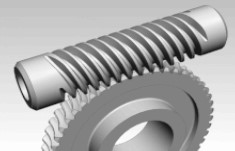

Worm Gears |

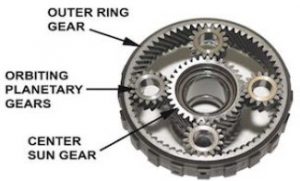

Planetary Gears |

| Gear Type | Pros | Cons | Applications |

| Spur Gears | Simple gear design | Sudden load Impact on teeth | Incinerators, dryers, kilns |

| Easiest to Manufacture | Entire load on one tooth at a time | ||

| Noisy at high Speeds | |||

| Rolling Contact | |||

| Helical Gears | Gradual sliding contact on teeth | Thrust bearings are required | Conveyors, Cranes, |

| Higher load capacity | More expensive | bucket elevators | |

| Quieter running | |||

| Double Helical | Gradual sliding contact on teeth | Alignment is critical | Turbines, Mills, |

| Gears | Higher load capacity | More expensive | high load applications |

| Quieter running | |||

| Thrust bearing are not required | |||

| Straight Bevel | Gear axles are at right angles | Rolling contact | 90 degree drive transfer |

| Gears | Easy to manufacture | Noisy at high Speeds | |

| Axial Thrust | |||

| Spiral (Helical) | Sliding contact mesh | Thrust bearings are required | Pulverisers, cooling towers, |

| Bevel Gears | Quiet running | travel drives for cranes, | |

| Higher load capacity | helicopter gears, conveyors | ||

| Rack and Pinion | Simple design | Entire load on one tooth at a time | Vehicle steering, conveyors, |

| Easy to manufacture | machine tools | ||

| Planetary Gears | High torque capacity | Expensive to manufacture | Wind turbines, crushers, |

| Large reduction ratios | rollers, propellers, | ||

| Compact | pump drives | ||

| Usually have helical gears | |||

| Worm Gears | Compact right angle drive | Low efficency | Lifts, cutting and forming, |

| Self locking | Produces a lot of heat | food mixers, mulcher drives | |

| Higher load capacity | Expensive to manufacture | ||

| Very quiet | |||

| Multitooth contact |

Where used and which lubricant?

These same gears are also used in automotive and off-road mobile equipment. The correct gearing system with a high-performance lubricant such as SWEPCO 201, 202, 203, 204, 210, 212, 164, and 222 can function well for a long time.

Contact us if you have a question about which lubricant you can use best!

Source: SWEPCO®