Oil Filters

The primary function of oil filters are to trap and remove contaminates and particulates, so they are not carried to the bearings and other surfaces and orifices with close tolerances. Proper installation and maintenance are required for the filter to work as designed.

In hydraulic, circulating, and large compressors systems cartage type filters are commonly used prior to a pump or in a kidney loop to filter the oil. Filters may be built into the system or made portable to service several sumps or reservoirs. Pressure gauges before and after the filters are used to determine if it is time to change the filters. A drop in pressure after the filter indicates that the filter is near the end of its useful life.

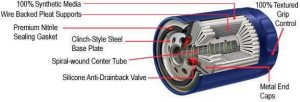

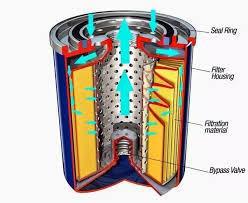

Most engine oil filters are screw on types although there are a few cartage types along with centrifugal and auxiliary filters. The oil comes from the oil pump to the outside holes, through the filter material to the center then out to the engine.

There is an anti-drain back valve to prevent the oil from flowing back to the sump when the engine is off, so the filter is always full of oil. There is a pressure release valve at the end of the filter to allow oil to flow through the filter in case the filter becomes plugged or the oil is too viscous due to cold weather to provide adequate flow to protect the engine. Some engines will have a full flow filter with a 10 micron or larger filter element to catch soot and metal particles, followed by a by-pass filter with a 5-micron filter to clean the oil.

There are varying opinions about whether to pre-fill a filter prior to installation. The major concern is that it takes 5 to 10 seconds longer for oil pressure to be achieved and full flow through empty filter verses a pre-filled filter. Some engines require high oil pressure to actuate the fuel injectors, the engine will not start until proper pressure is obtained. The engines that do start are running on residual oil until the filter is filled, usually 10-15 seconds.

If it is decided to pre-fill the filter, it is recommended that the oil is added to the outside holes, NOT the center hole.

The center hole is for clean filtered oil ONLY!

The center hole is for clean filtered oil ONLY!

Some engine manufacturers recommend not to pre-fill the filters as there have been issues with contaminated oil being introduced into the engine from filling the center hole. Some engines have a piston and/or cylinder cooling oil spray with very small spray nozzles, particles could plug the nozzle causing the cylinder and piston to overheat and fail.

There are several cases cited with warranties were not honored because small bits of aluminum foil from the oil container seal or plastic particles from the plastic bottle had plugged the cooling oil nozzles after an oil change where the filter had been pre-filled. New oil out of a container or through a nozzle from a bulk storage bin may have contaminates that the filter can address prior to the oil contacting vital engine parts.

It is recommended that a light coating of oil be smeared on the seal ring to help make a good seal and facilitate ease of removal. Check your owner’s manual for the proper filter to use when changing oil or just changing filters.

“To keep it running…!”

Source: SWEPCO®