SWEPCO 724 Ultra AW Wire Rope Lubricant

Price on request

- Description

- Additional information

- Properties

- Benefits

- Markets

- Applications

- Technical Details

Description

SWEPCO 724 Ultra AW Wire Rope Lubricant is a high viscosity semi-fluid lubricant, especially formulated for lubrication and protection of expensive wire ropes and cables.

- High performance synthetic base stocks and state-of-the-art overbased calcium sulfonate chemistry provide industry leading extreme pressure, anti-wear and corrosion protection.

- Coats exteriors to eliminate abrasive wear and corrosion.

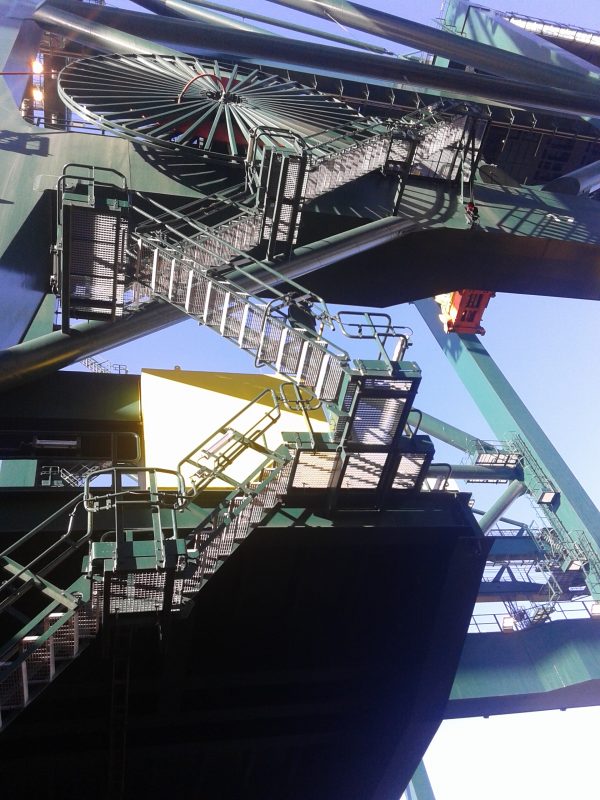

- Prolongs the life of wire rope, sheaves, pulleys, drums, guides, pins and rollers in a variety of applications, including cranes, hoists, marine tow and mooring lines, dockside cables, aerial tramways, dredges, draglines, mining, elevators and many other applications in construction, mining, transportation and manufacturing.

For a similar product like SWEPCO 724 Ultra AW Wire Rope Lubricant, but without a diluent, please refer to SWEPCO 723 HVG Anti-Wear Wire Rope Lubricant.

To be able to add SWEPCO 723 HVG Anti-Wear Wire Rope Lubricant and SWEPCO 724 Ultra AW Wire Rope Lubricant in a perfect way, we recommend the use of a MASTO smeerunit.

Additional information

| Brand | SWEPCO |

|---|---|

| Density | 7,279 |

| Shipping | Drum (186 kg./208 liter), Pail (16 kg./19 liter) |

- Unsurpassed Protection;

- Withstands the heaviest loads; prolongs life of expensive wire ropes;

- Excellent Rust & Corrosion Resistance;

- Won't wash or sling off;

- Clear to allow easier Wire Rope Inspection;

- Won't Harden even in low Temperatures;

- Slowly Evaporating Solvent Improves Application Flexibility.

- Extends life of heavily loaded wire rope, cables, drums, sheaves, guides, pulleys, pins and rollers;

- Exceptional EP performance (800 kg weld load);

- Tough, non-drying coating bonds tenaciously to protect from abrasive wear;

- Doesnt build-up or harden like asphalt based products;

- Superior resistance to water, salt spray, acid rain and other corrosives;

- Improves load carrying capability;

- Wont wash or sling off;

- Translucent color permits easier inspection of wire ropes;

- Extends lubrication intervals -- Saves labor dollars;

- Apply by brush, swab or pressure lubricators;

- Environmentally responsible;

- No hazardous lead, trichloroethylene or offensive odors.

- Heavy Construction;

- Manufacturing;

- Mining;

- Transportation.

- Cranes;

- Hoists;

- Marine tow and mooring lines;

- Dockside cables;

- Aerial tramways;

- Dredges;

- Draglines;

- Mining;

- Elevators;

- Other applications in construction, mining, transportation and manufacturing.

Would you like to receive more information about this product? Please contact us at info@stratson.nl.

We can send you per e-mail, for example:

Case studies,

Technical Data sheets &

Material Safety Data Sheets.

Let us know by email what information you wish to receive.