SWEPCO 722 HiTemp Chain & Roller Lubricant H1

- Description

- KEY BENEFITS

- Typical Physical Characteristics

- Typical Performance Characteristics

Description

SWEPCO 722 HiTemp Chain & Roller Lubricant H1 is specifically formulated for clean, energy efficient lubrication of roller chain assemblies in high temperature environments. It is well suited for lubrication of chains, rollers, bearings, pins, cams, gears and slideways in baking, annealing, curing and drying processes involved in manufacture of many plastic, glass, paper, wood, textile, carpet, tile and cement products and other high temperature applications.

Because of its superior ashless, low volatility chemistry, SWEPCO 722 provides outstanding protection from wear, rust, oxidation and corrosion without forming carbon, varnish, sludge, smoke or objectionable odors.

NSF H1 and biodegradable so it can be used in food plants and environmentally sensitive areas.

Expected in Europe: March 2019.

|

|

|

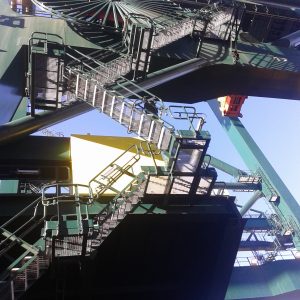

SWEPCO 722 provides clean, high performance lubrication in high temperature chain applications. |

| DRYING & CURING | BAKING | HEAT TREATING LINES |

DESCRIPTION & PURPOSE

SWEPCO 722 HiTemp Chain & Roller Lubricant is a versatile lubricant which provides superior performance in a wide range of high temperature chain and roller applications. It makes chains, bearings, rollers, gears, cams, pins, slides and slideways operate longer, cooler, smoother, quieter and more efficiently and improves equipment life and reliability.

FORMULATED FOR HIGH TEMPERATURE CHAIN & ROLLER APPLICATIONS

With an upper limit of 500+°F, SWEPCO 722 is designed to provide superior lubrication of chain assemblies operating in a variety of high temperature commercial and industrial oven, drying, curing, annealing, heat treating, tenter, kiln and refractory processes. Chain, roller and other automatic conveyance assemblies in paper, wood, glass, carpet, textile, plastics, brick, tile and cement products manufacturing are just a few of the target applications.

CLEAN, DEPOSIT-FREE PEFORMANCE

Many lubricants form troublesome carbon, varnish or gum type deposits in high temperature applications. But SWEPCO 722’s superior ashless, low volatility chemistry eliminates these deposits. That means conveying assemblies and chain components require less cleaning, reducing both labor and downtime.

SUPERIOR WEAR PROTECTION FOR HIGHLY LOADED LINES

SWEPCO 722’s excellent anti-wear and extreme pressure properties insure protection of chain and conveyor components from wear in highly loaded production lines.

REDUCES LUBRICANT CONSUMPTION

SWEPCO 722’s low volatility, high performance oxidation inhibitors and high viscosity index mean it lubricates longer without volatilizing. And that means lower lubricant consumption rates and lower lubricant costs.

IMPROVES ENERGY EFFICIENCY

Lack of deposits and clean fluid film lubrication also improves energy efficiency in many applications. Excellent lubricity and freedom from deposits reduces friction and drag, particularly on curved sections of conveyor lines. Well lubricated lines pull fewer amps and that means additional profit to the bottom line.

RUST & CORROSION PROTECTION

High temperature applications can pose special challenges for control of rust and corrosion, especially in industrial processes where corrosive materials often exist. That is why SWEPCO 722 is formulated with highly effective rust and corrosion inhibitors designed to protect vital process line components and keep uptime to a maximum.

REDUCES SMOKE & ELIMINATES ODORS

Smoke and odors are concerns in many high temperature applications. SWEPCO 722’s low volatility characteristics reduce the likelihood of smoke and eliminates objectionable odors.

- Outstanding performance in high heat applications in baking, drying & curing applications exceeding 500° F

- Can be used for lubrication of chains, rollers, cams, bearings, gears, slides, slideways and other components of industrial process lines

- Ashless, low volatility chemistry eliminates carbon & varnish deposits

- Reduction of deposits improves energy efficiency

- Superior high temperature performance reduces lubricant consumption

- Excellent protection from wear, rust and corrosion

- Prolongs chain and chain part life

- Reduces downtime and labor required for cleaning

- Reduces smoke

- Eliminates objectionable odors

NSF H1, biodegradable

SAE Grade ............................................................ Approx 20

ISO Grade .......................................................................... 68

Density, @ 60°F, lbs/gal ................................................ 7.88

Density, @ 60°F, kg/l .................................................... 0.94

Viscosity, cSt @ 40°C ..................................................... 72.6

Viscosity, cSt @ 100°C .................................................. 11.77

Viscosity Index ................................................................. 157

Flash Point,COC, °F(°C) ........................................ 560 (293)

Fire Point, °F(°C) ................................................... 640 (338)

Pour Point, °F(°C) ............................................... -40F(-40C)

Ash, % Wgt ................................................................. <0.001

Water, % Wgt, max ......................................................... 0.05

Total Acid Number, max ...................................................0.5

Color ................................................................... Light Yellow

Evaporation Loss, ASTM D-972, 6.5 hrs @400°F ...............1

Carbon Residue, ASTM D-189, % .....................................0.1

Wear, 4-ball scar, 40kg @167°F, mm ............................ 0.25

Rust, ASTM D-665, Distilled Water ...............................Pass

Rust, ASTM D-665, Sea Water .......................................Pass

Biodegradable OECD 301B...........................................>60%

NSF - H1