November 2021

Choosing the right hydraulic fluid

A bit of history: Engine oils have been used in a variety of applications mainly since they are available almost everywhere in the world and fit the old belief that “oil is oil” that will work at least for a while. Engine oils are designed for use in engines and may not be the best choice for other applications. Engine oils have very poor water separation and tend to emulsify water which leads to rust, wear, high operating temperatures due [...]

July 2021

Proper Bearing Storage

The importance of proper bearing storage is often underestimated. The conditions under which bearings and seals are stored can have an adverse effect on their performance. Inventory control can also play an important role in performance, particularly if seals are involved. Therefore, it is recommended to practice a “first in, first out” inventory policy. Storage conditions To maximize the service life of bearings, SWEPCO recommends the following basic housekeeping practices: Store bearings flat, in a vibration-free, dry area with a cool, steady [...]

November 2020

Internal Combustion Engine

The future of the internal combustion engine (ICE) There is a lot of speculation about what will become of the internal combustion engine that has served mankind for over a century. Concerns about climate change, pollution, energy and energy efficiency, resources, while preserving mobility, industry, and personal freedoms. States such as California and several foreign countries have banned the sale of ICE after 2035 and are pushing total electric vehicles. A recent IMLA (Independent Lubricant Manufacturers Association) townhall discussed a meeting between [...]

Which Grease do I use?

Which Grease works Best for YOUR bearing application? Bearings are everywhere and used in a wide variety of applications. The same question is asked when presented with a new or different application, “Which Grease do I use?” Food Grade: The choices are limited to SWEPCO 115 and 116, depending upon the speed, load and temperature range. High Temperature: For extreme temperatures above 400°F (204°C) and areas where a non-melt grease is preferred then SWEPCO 101, 102, or 104 grease depending upon whether the [...]

SWEPCO and RACING

SWEPCO traditionally has been focused on industrial and fleet lubrication where high performance and specialty lubricants are needed. Value added products generally were viewed as unnecessary for everyday personal transportation and leisure vehicles. But what about SWEPCO and RACING? Over time, week-end racers, off-roaders, and even racing professionals were hearing about these awesome products from an unknown company in Texas that were outperforming the well-known brands. Word of mouth spread the stories of high-performance lubricants that work in the most [...]

Changing Lubricants on Open Gears

All open gears need lubrication to operate properly and prevent damage to the gear teeth. These gear sets are found on ball mills, rod mills, grinders, draglines, power shovels, and crushers. There is usually a bull gear with 1 or more pinion gears that drive the larger bull gear. One of the objections that come up when changing to SWEPCO lubricants is cleaning the old lubricant off the gear sets. Many open lubricants are asphaltic based that build up on [...]

INDUSTRIAL GEARS

Industrial gears are used everywhere to change speed, direction, and torque of a drive from a power source such as electric motors or engines. Gears have been used since the 1500’s and originally made of wood and lubricated with animal fat. In the 1700’s iron was introduced which allowed the gearboxes to handle greater loads with significant reduction in size and weight. That trend continues today. A gear box made today is one-third the weight and size of one made [...]

July 2020

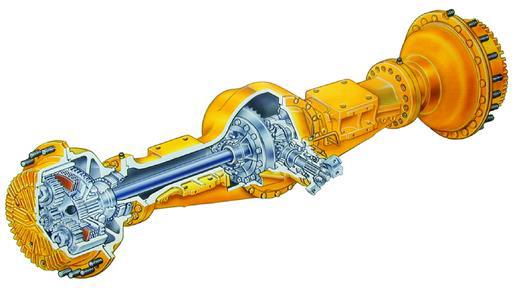

Wet Brake Systems

Construction equipment, farm equipment, forklifts, heavy duty trucks, and mining equipment have been utilizing wet brake systems for years. Wet brakes are a system where the braking surfaces are operated, lubricated, and cooled with oil. The advantages of this system are the brakes are not exposed to dirt, water, or other contaminates, they are cooled during braking operations to prevent warping and are lubricated to reduce wear. If well maintained and not damaged, they can last the life of [...]

June 2020

Oil Filters

The primary function of oil filters are to trap and remove contaminates and particulates, so they are not carried to the bearings and other surfaces and orifices with close tolerances. Proper installation and maintenance are required for the filter to work as designed. In hydraulic, circulating, and large compressors systems cartage type filters are commonly used prior to a pump or in a kidney loop to filter the oil. Filters may be built into the system or made portable to [...]

May 2020

Air Compressor Maintenance

Air compressors do more than provide air for the low tire on your car. They are a major piece of equipment in most manufacturing, processing, and production facilities. You will find them in repair shops, farms, and dentist offices just to name a few. All of them need routine maintenance to keep them in top working order. Air compressor maintenance is essential for your daily operations. Air Compressor Maintenance First, check the owner’s manual, there you will find a list of [...]

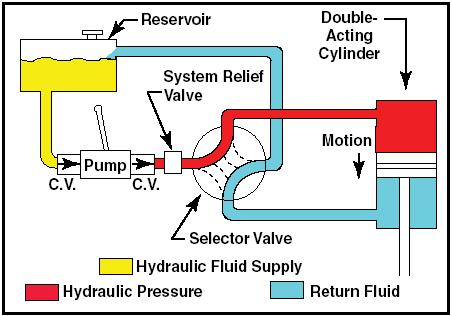

Care and Maintenance of Hydraulic Systems

Care and Maintenance of Hydraulic Systems is essential. You see or are affected by hydraulic systems all the time. Most construction and farm equipment use hydraulics. Many buildings 4 stories or less use hydraulic elevators. Hydraulic cranes, lifts, and tow trucks all use hydraulics. This list quite long and they all use the same common parts: A reservoir or sump to supply fluid for the system, cooling and deairing of the return fluid. Pumps of various types to supply pressure for [...]

February 2020

Trends in biodegradable lubricants

Trends in biodegradable lubricants Biodegradable lubricants such as animal fats and seed oils were used for centuries prior to the discovery of oil. Whale oil was a popular lubricant of choice until the 1900’s. There were several issues with using animal fats and seed oils, they lacked oxidative stability and low temperature properties. Interest in biodegradables became popular during World War I and II due to oil rationing and shortages, then again during the 1978 OPEC oil embargo. Advantages of Biodegradables Biodegradables offer [...]

Cranes

There are a wide variety of crane designs and they all need lubrication. Some are permanent structures for stevedoring or overhead cranes in manufacturing. Others are the cage type that usually must be assembled on-site and then dis-assembled to move to different locations. These cranes have pulleys, bearings and ring bearings that are heavily loaded. SWEPCO 101 and 123 have proven to extend the bearing life in these applications. The Wire ropes require quality lubricants to prevent wear, corrosion and breakage. [...]

January 2020

SWEPCO 770 Fire Resistant Hydraulic Fluid

SWEPCO 770 Fire Resistant Hydraulic Fluid is a fully synthetic high-performance hydraulic fluid formulated for use in areas where potential fire hazards exist. SWEPCO 770 is an ester-based fluid that is non-toxic and fully biodegradable in less than 28 days. SWEPCO 770 Fire Resistant Hydraulic Fluid: Flash point above 315°C (600°F) well above typical mineral oil based hydraulic fluids. Does not readily ignite or burn during normal use. Meets HFD-U specification for fire resistant fluids. Rapidly separates from water for easy removal. Has excellent wear resistance [...]

December 2019

Food Grade Lubricants

There is a lot of confusion about Food Grade Lubricants as to where they can be used, are they safe, and what do the different classifications mean? Food grade lubricants are designed for use wherever food is handled, processed or packaged. Everywhere from the farm, ocean, or fresh water to your local market. These lubricants have different classifications to indicate where and how they can be used. H-1 Lubricants H-1 Lubricants are for use in processing and packaging equipment along with food [...]

SWEPCO 165 Universal Extreme Pressure Grease in a NLGI #1

As of next month SWEPCO 165 Universal Extreme Pressure Grease in a NLGI #1 will be available in Europe! This high-performance grease is almost also available is a NLGI #1 or 165 Light in Europe, at the same price as the NLGI #2. Advantages: The #1 pumps at -20°F(-29°C) for those low temperature applications. Excellent for use in winter months or year around in cold climates. Excellent wear resistance for long bearing life. Works well in wet and damp applications. Alkaline reserve to resist corrosive [...]

November 2019

Tractor Lubrication

Farms are found everywhere around the world with the exceptions of the north and south poles and uninhabitable areas. Humanity has modified the earth to raise food where nothing edible grew before. There are usually many pieces of equipment on a farm and one of the key implements is the tractor. The tractor has evolved from a simple machine to replace animals into a complex multifunctional and versatile implement complete with climate control, WIFI, and GPS systems. Currently self-driving [...]

Concrete Mixing Trucks

Concrete mixing trucks are on construction sites around the world and all of them need quality high performance lubricants. Starting from the from the front and working towards the back… Most of these units are diesel powered, SWEPCO 310 Premier Engine Oil SAE 15W40 or 10W30 will provide excellent service, quieter operation, reduced maintenance, and longer drains in most cases. The SWEPCO 310 is backward compatible for older units and acceptable for use in gasoline and natural gas-powered trucks. Moving to the under [...]

October 2019

Food Processing Machinery

Food Processing Machinery Part 1 Although there are many types of food processing equipment, Extruder and Pellet Mills will be discussed in this technical bulletin. *Extruders: Starches, sugars, proteins, dyes, minerals, and other materials are blended in powder form and then mixed with water and steam to a desired texture and temperature. This mixture is pushed through a die or extruded, and cut to length to make breakfast cereal, ready to eat snacks, and other edible items. The same process is used [...]

Hydraulic Hammer Lubrication

Hydraulic hammers are commonly used in construction and demolition to break up roads, sidewalks, site pads, rocks, or any hard object that needs to be reduced in size for removal or further processing. These tools can be attached to a wide variety of equipment with a hydraulic system. They are commonly attached to backhoes, steer skids, and loaders. The chisel sides up and down with extreme force to break up the concrete, rocks, etc. A hammer paste is recommended to [...]

September 2019

Lubrication of a Drawbridge and related Equipment

Follow a water way, river, stream, or canal, and you may find a drawbridge. A drawbridge is a passable span across the water that can be raised for ships and boats to pass and then lowered for normal use. There are thousands of drawbridges in the state of Florida alone, not to mention the world-famous London Bridge and many more. Most of these bridges are raised and lowered by a set of gears. Usually there is a drive which [...]

August 2019

Valve Lubrication with SWEPCO 165

Valve Lubrication with SWEPCO 165. Wherever there is a liquid or gas that is moved through a pipe or tube regardless of length, it will have a valve that needs lubrication. Years ago, most valves were lubricated with a few drops of motor oil; however, today’s equipment is much more demanding. Gate valves Gate valves require grease to be injected into the valve cavity to displace fluids and contaminates while acting a barrier to prevent further ingress. The grease acts as a [...]

July 2019

SWEPCO 303 Premium Multi-Grade Automotive Engine Oil

SWEPCO 303 Premium Multi-Grade Automotive Engine Oil Now meets API SN Plus AND Dexos™ 1 Generation 2. API SN Plus addresses current issues prior to the release of the next engine oil specification update due out in late 2020 or early 2021. The use of turbocharged, direct injection gasoline engines has increased significantly over the last few years to improve fuel economy and efficiency with lighter weight. The higher power density of these engines makes them prone to an abnormal combustion event [...]

Expansion SWEPCO 755 & 757 viscosities

SWEPCO has expanded the available viscosities for SWEPCO 755 Premium Food Grade Hydraulic Oil and SWEPCO 757 Premium Food Grade Gear & Bearing Oil. These state-of-the-art fully synthetic lubricants are ideal for use anywhere food is grown, processed, handled, and packaged. SWEPCO 755 Premium Food Grade Hydraulic Oil SWEPCO 755 Premium Food Grade Hydraulic Oil is now available in ISO grades: 22, 32, 46, 68, and 100. The ISO 22 has an impressive -94°F (-70°C) pour point. This makes it ideal [...]

Engine Oil Specifications Updates-2019

There is still some confusion and lack of information about which engine oil to use these days and limitations from the OEM’s. Let’s review SWEPCO Engine Oil’s… Specifications they meet and where to be used: SWEPCO 306 … Meets or exceeds API CI-4+ and SM (except for the 5W30 which only meets SL). SWEPCO 306 is recommended for off road diesel engines prior to 2010 and over the road engines prior to 2007. It can also be specified in gasoline engines requiring [...]

Understanding Technical Data Sheets for Oils

Most lubricant suppliers provide a Technical Data Sheet or Sales Brochure that list the typical physical characteristics and typical performance properties of their products. These typical properties provide results to various physical and chemical tests that are performed on the batch of product. A frequently asked question is “What does this result mean? Is it a good value or average?” Reading test results can be confusing. In certain tests, the higher the result, the better the performance. And in [...]

WHY TIMKEN OK LOAD RATINGS SHOULD NOT BE A PRIMARY MEASURE OF EP PERFORMANCE

When reviewing the technical data sheet for a lubricant or lubricant specifi-cations for a piece of equipment, you will often see references to the Timken OK Load test. So what does it mean when one lubricant has a 35-pound Timken OK Load rating and another has a 100-pound Timken OK Load rating? The truth is … it may have very little relevance to the amount of EP protection you are getting. There are basically three reasons for this: First, the Timken Test [...]

Understanding Technical Data Sheets for Grease

Most lubricant suppliers provide a Technical Data Sheet or Sales Brochure that list the typical physical characteristics and typical performance properties of their products. These typical properties provide results to various physical and chemical tests that are performed on the batch of product. A frequently asked question is “What does this result mean? Is it a good value or average?” Reading test results can be confusing. In certain tests, the higher the result, the better the performance. And in [...]

January 2019

Reading Test Results

From time to time you and we run across a competitive product brochure or an OEM (Original Equipment Manufacturer) requirement with test methods that do not follow the standard ASTM (American Society for Testing and Materials) nomenclature or results. There are a number of different standards in place such as: the German DIN (Deutsche Industrie Norm), ISO (International Organization for Standardization), and SASO (Saudi Standards. Metrology and Quality, Org) to name a few. This makes reading test results, especially for [...]

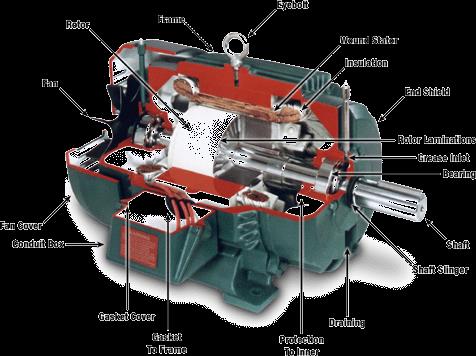

Lubricating Electric Motors

Lubricating Electric Motors Electric motors contain bearings that require lubrication. Most electric motors use grease. Ideally the grease should have: dropping point above 204°C (400°F), low bleed characteristics, excellent resistance to high-temperature oxidation, and good anti-wear properties. Typical thickeners include lithium, calcium, bentonite, and polyurea. One of the biggest issues is that these thickeners are not compatible with each other which will cause problems and bearing failure if greases are mixed randomly. If the bearing size is known or can be determined, the amount of grease [...]

September 2018

SWEPCO Food Grade Oils

SWEPCO Food Grade Oils SWEPCO Food Grade Oils are used in an increasing number of locations with excellent results. SWEPCO has USDA/NFS H-1 registered and Canada Health compliant Food Grade Compressor (SWEPCO 750), Hydraulic (SWEPCO 755), and Gear (SWEPCO 757) oils available for use in food processing facilities and other applications. These are fully synthetic fluids designed for use in areas where the product may have incidental contact with food. SWEPCO 750 Premium Food Grade Compressor Oil SWEPCO 750 has superior anti-wear, [...]

L.E.T.S.

L.E.T.S. Acronyms are everywhere and are part of everyday life. L.E.T.S. is a very important acronym in the world of lubrication, as it describes the critical information needed to make a product recommendation for that application. LOAD; What are the load requirements? Is the load constant or is shock loading involved? Is the load light or heavy? This information is vital to the long-term performance of the recommended product. ENVIRONMENT; Is the equipment in a clean dust free environment or outside? Is the application [...]

May 2018

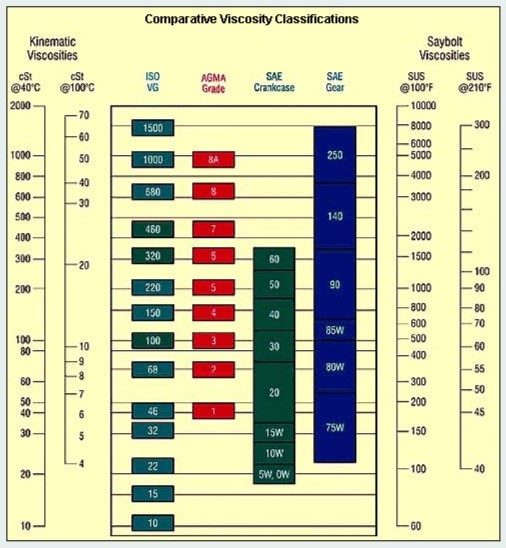

Viscosity, wading through the numbers

Viscosity, wading through the numbers: Simply put, viscosity is the measure of resistance to flow, the higher the number the greater the resistance. Seems easy enough until one discovers that there are several ways to describe the same viscosity. Stationary or mobile? An easy way to look at it is to consider the application: is the application stationary or mobile? A general rule of thumb would be if the application is stationary then the ISO viscosity grade (VG) applies and if it is [...]

February 2018

Renewable Fuels part 2 Green Gasoline

Renewable Fuels part 2 Green Gasoline The Renewable Fuels or “Green Gasoline” comes from the Clean Air Act in an effort to reduce Green House Gases (GHG) from our air. These Green House Gases are mostly carbon dioxide and carbon monoxide from the engine combustion process, burning of fuels, and breathing. When more carbon dioxide is generated than the plant life on planet earth can utilize, the excess traps heat like a green house and raises the average temperature, commonly [...]

Renewable Fuels part 1 Biodiesel

Renewable Fuels part 1 Biodiesel There has been a lot of hype about renewable fuels over the last few years. These advances in fuel sources have been driven by The Clean Air Act to reduce smog producing exhaust, Green House Gases such as Carbon Dioxide, and the desire to reduce dependence upon foreign oil. Biodiesel: Biodiesel has been around for many years now and after a [...]

January 2018

Extreme Pressure Additives and Function

Extreme Pressure Additives and Function You will find the word Extreme Pressure (EP) on labels for a variety of lubricants, especially on gear oils and greases. The function of these additives is to prevent metal to metal contact during times of high load, shock load, high temperature, and slow speeds during start up or shut down. There are several ways this can be accomplished. When equipment is running normally, the lubricant should provide a fluid film between the metal surfaces to [...]

Trouble shooting a Noisy Gearbox

Trouble shooting a Noisy Gearbox This is we think another Notes from the Lab with some very interesting info, Trouble shooting a Noisy Gearbox has cost a lot of people a lot of time and …. Whether it is a stationary gearbox, a differential or a transmission, a gearbox making an abnormal noise usually is a warning sign of a problem. There is a certain amount of noise to be expected in a manufacturing environment and less in an automotive system. The noise can [...]

December 2017

Gears help to move the world

Gears help to move the world regardless of the power source or application, gears and gearboxes are everywhere. From transportation to manufacturing and general industrial use gears are part of everyday life and using the correct lubricant is critical for long equipment life. Most applications fall under automotive or industrial use, open gears will be discussed later. Automotive gear oils face many challenges and have several levels of performance defined for use. The first level of specifications come from the American Petroleum [...]

July 2017

Keeping up with ATF (Automatic Transmission Fluids)

Keeping up with ATF (Automatic Transmission Fluids) Prior to 2000 about 80% of the ATF market was covered by General Motors Dexron III, Ford’s Mercon or Chrysler’s ATF +4 standards and specifications. It was easy for an installer, mechanic, or do-it-yourself person to figure out which fluid to use for make-up or replacement fluid. Lubricant marketers only had to carry a couple of aftermarket fluids to meet a majority of the demands. Today Dexron III/Mercon fluids account for less than [...]

Changing Lubricant Brands, Murphy’s law applicable?

Changing Lubricant Brands, Murphy’s law applicable? One of the most frequently asked questions we receive concern the changeover from brand X to SWEPCO products. All new and many current customers must weigh the risks that may occur when switching Brands due to possible incompatibilities and others potential issues. Contrary to popular belief not all lubricants are the same and Murphy’s law “Anything that can go wrong will go wrong” still shows up at the most inopportune times. There are a variety of [...]

Engine Oils in the News

Engine Oils in the News Every day we face common objections and resistance to switching over to SWEPCO products. One of the most common objections is that they can’t use SWEPCO products because the manual doesn’t specifically list SWEPCO. While SWEPCO products are not listed in many OEM manuals by name, we are in practically ALL OEM manuals by virtue of meeting the industry specification required. We are also face with warrantees that claim no coverage unless certain products are [...]

Engine Oils specifications

Engine Oil Specifications: There has been a great deal of comment lately concerning engine oils. The State of California is looking to remove all of the oils that only meet obsolete specifications’ from the store shelves. API (American Petroleum Institute) has released new Heavy Duty Diesel Engine Oils Specifications CK-4 and FA-4. New Diesel Engines from Ford exhibit excess valve train wear with these new oil specification oils, and other news items. Engine oils have been divided into two (2) main [...]

April 2017

Lubricating Natural Gas Engines

Lubricating Natural Gas Engines Years ago Natural Gas Engines were usually only found in corn fields for irrigation or as a pump drive at a natural gas well. Today they are everywhere and growing in number. These units are being used for transportation, power generation, pumping stations, and agriculture. Many major cities have converted city vehicles, buses, and public transportation to CNG, LPG, or LNG. Companies like UPS and FedEx are switching many of their short haul trucks to natural [...]

March 2017

What is GF-6 and PC-11? Or Upcoming engine oil changes!

What is GF-6 and PC-11? Or Upcoming engine oil changes! You may have seen, heard, or read about future changes in engine oils and wondered “Why?” It all has to do with the Clean Air Act and air quality. There are still major air quality issues in large cities and now in developing countries. The major polluter has been identified as the internal combustion engine, both gasoline and diesel. CAFÉ The U.S. Congress has set a goal of 50 mile per gallon for [...]

Building A High Performance Hydraulic Oil

Building A High Performance Hydraulic Oil Do you know what the VI is for SWEPCO 703? Do you know why such a high VI gives our products an advantage? What percentage increase does 703 offer in efficiency of the equipment? After you read this Technical bulletin you will be able to answer these questions and know why we are building A High Performance Hydraulic Oil for you (or actually 2…) More demanding, tighter tolerances and wider operating temperatures Hydraulic systems are widely used in a variety [...]

Syntheon: Advanced Base Fluid Technology

Introducing Syntheon: Advanced Base Fluid Technology Walk into any auto parts store and in the engine oil area you will find a variety of products offering full synthetic, partial synthetic, synthetic blends, the list goes on and on. A key point to remember is that according to a 1999 U.S. Court case the term Synthetic is a marketing term rather than a scientific term. current definition of the term synthetic Many of us started in this business with the understanding that the term synthetic [...]

High Copper Levels in Used Oil Analysis

High Copper Levels in Used Oil Analysis reasons for concern? From time to time traces of Copper show up in used oil analysis reports ranging from a few PPM to over a 1000 PPM. Generally, high Copper levels are not a cause for concern unless other wear metals are present in unusual levels. Copper is a soft metal so it will not promote wear, abrasion, or other damage in equipment. Copper is a component of Bronze and Brass which are used [...]

February 2017

Total Cost of Ownership in a different perspective

Total Cost of Ownership in a different perspective We have received an interesting document from SWEPCO Head Office of looking at total cost of ownership. Please read and it might help you getting a more clear picture of SWEPCO compared to other lube manufacturers. We all have different ways we present SWEPCO products. We use buzzwords, demonstrations, and other valuable tools we have learned from experience. One successful way that we teach at our Lubricants Training School is to really focus [...]

January 2017

The Importance of Keeping Lubricants Dry

The Importance of Keeping Lubricants Dry Water is everywhere and tends to get into everything. Plants, animals, and people need water to live, however water is not desirable in lubricants. Let us look at how water gets into equipment, the damage it does, how to test for water and how to keep it out of your lubricants and equipment. The Importance of Keeping Lubricants Dry is often underestimated. Clogged breathers There is water in the air and it is more apparent on humid [...]

December 2016

Preparing a Diesel Engine for Winter

Preparing a Diesel Engine for Winter Now is the time to switch to the SWEPCO 501 Premium Diesel Fuel Improver Winter version to protect your equipment when a cold snap occurs and possibly causes problems. Once a fuel has gelled, it must be warmed up and completely thawed to treat it. 501 Winter improves the Cetane Number in diesel fuel for easier starting, shorter warm up time, and less white smoke at start up. SWEPCO 501 Premium Diesel Fuel Improver Winter version contains wax modifying [...]

Procedure for Changing from Mineral Oil to Biodegradable Fluids

Procedure for changing from mineral oil to biodegradable fluids: As more and more governments are pushing for “green” alternatives, customers may be required to use biodegradable lubricants in their equipment. This is becoming more common in reclamation projects, environmentally sensitive areas, and in some new construction. Important is a correct procedure for changing from mineral oil to biodegradable fluids. Varnish, sludge, and deposits tend to build up in hot zones and “dead zones” in gear boxes, hydraulic, and hydrostatic equipment. Most mineral oil based [...]

ISO Cleanliness Code

What is the ISO Cleanliness Code of your Oil? As we visit new and existing customers we hear sometimes the question: What is your ISO Cleanliness Code? or What are your ISO numbers? on a certain oil. What they are referring to is the ISO 4406:1999 standard for oil cleanliness. In 1999 the International Standards Organization developed a system to rate and quantify the number of particles in the greater than or equal to 4 microns, 6 microns and 14-micron range. Please note [...]

November 2016

Biodegradable Lubricants

Defining Biodegradable Lubricants Biodegradable lubricants have been around for thousands of years. Ancient man used olive oil, palm oil, or other plant based oils to lubricate axles, slides, and other moving objects. These oils were not oxidative resistant and required frequent replacement. Whale oil was used for many applications up until the mid-twentieth century due to its excellent lubricity and improved oxidation resistance. Biodegradable lubricants have been around for thousands of years. Ancient man used olive oil, palm oil, or other [...]

The Effects of Over-Greasing a Bearing

What are the Effects of Over-Greasing a Bearing? Over 35% of all bearing failures are due to improper lubrication. These include: over-greasing; under-greasing; wrong grease for the application; Or a combination. Many people have been instructed to attach a grease gun to a bearing and keep pumping the lever until grease comes out somewhere. This is acceptable for hinge pins and other applications where old grease and contaminates need to be removed and not cause damage. A typical manual grease gun can generate 15,000 psi of [...]

September 2016

Guidelines for Grease Operating Temperatures

We would like to share some Guidelines for Grease Operating Temperatures. This is about as well High as Low Temperatures! In 1933 a group of Grease Manufacturers met to address common grease industry issues and to standardize lubricating grease properties. The National Lubricating Grease Institute was born and has served the lubricating grease industry for over 80 years. The Annual Meetings address various issues, regulations, and provide training in the manufacture and application of lubricating grease. There have been several presentations [...]

February 2016

EXCITING NEW CHEMISTRY

EXCITING NEW CHEMISTRY MAKING SWEPCO LUBRICANTS BETTER THAN EVER ! Research and Development is a core activity at SWEPCO Home Office. Our laboratory is at work every single day in search of opportunities to improve our product line. As a result this brings interesting new Chemistry! We are committed to providing the resources that are needed to keep us … not just competitive … but in a position of leadership, in a rapidly changing lubrication market. This commitment is absolutely essential [...]

SWEPCO ISO 21469 Certified

SWEPCO ISO 21469 Certified February 3, 2016 Notes from the Lab: ISO 21469 Good Manufacturing Practices For Food Grade Lubricants. For several decades, Food Grade Lubricants only required certification of the finish lubricant. This entailed a manufacturer sending a formulation, label, and sample to a certification organization for approval to sell the lubricant in food manufacturing and handling facilities. Materials used in making Food Grade lubricants are limited and must pass a variety of health, safety, and toxicological tests. There are the [...]