Care and Maintenance of Hydraulic Systems

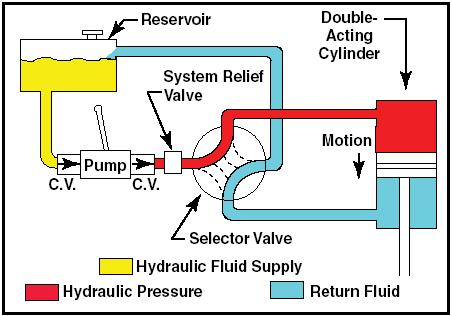

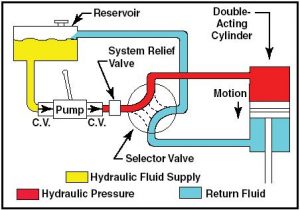

Care and Maintenance of Hydraulic Systems is essential. You see or are affected by hydraulic systems all the time. Most construction and farm equipment use hydraulics. Many buildings 4 stories or less use hydraulic elevators. Hydraulic cranes, lifts, and tow trucks all use hydraulics. This list quite long and they all use the same common parts:

- A reservoir or sump to supply fluid for the system, cooling and deairing of the return fluid.

- Pumps of various types to supply pressure for the system.

- Valves and servos to direct the fluid pressure and control the actuators.

- Pistons and actuators, the push and pull part of the system that makes things happen.

C.V is Check Valve

C.V is Check Valve

Simple hydraulic system

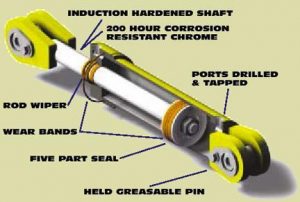

Hydraulic Piston or Actuator

Proper maintenance and periodic checks will keep a system working trouble free and saves you money. Ideally hydraulic system should be checked weekly for reliable continuous service.

Key Check Points:

- Check fluid levels, top off, if necessary, with the same fluid. Do not mix fluid brands, types or viscosities. Use the viscosity recommended by the equipment manufacturer.

- Inspect breather caps, filters, and fill screens. These must be kept clean and functioning to keep contaminates out of the system.

- Check filter indicators and/or pressure differential gauges. Replace any that show wear or negative values.

- Visually inspect all hoses, pipes, connections, and piston seals for leaks and frays. Hydraulic fluid leaks are common. They are a safety hazard, increase waste and oil usage, and cause equipment failure. Low oil levels can cause overheating, poor operation, pump cavitation, and other issues.

- Most systems should run at 110°F to 140°F (43°C to 60°C) and be easily checked via built in thermometers or hand-held devices.

- Look inside the reservoir or sump for signs of aeration and contamination. Air bubbles and foam will damage a pump. Aeration is usually caused by low fluid levels, air leaks in the suction seals, or too high of a viscosity due to cold fluid temperatures, the wrong fluid viscosity, or the fluid has oxidized and gone beyond its useful life. Drain or pump out any water in the reservoir.

- Listen to the pumps for signs of cavitation or unusual noises. Cavitation is the air that can gather in the areas of low pressure around an impeller. It damages the pump, decreases flow, and causes vibration if not treated.

- Inspect the fluid for color, odor and contaminates. Visual inspection will only detect excess contamination.

- Check the temperature of servos and valves, temperatures above 150°F (65°C) usually mean the valves are sticking or bypassing. Sluggish operation or jerking are signs of possible contamination.

- Electric motors should be checked for overheating and excessive electricity usage.

- Keep pistons and actuators clean to extend seal life and keep out contaminates.

Hydraulic Fluids:

The hydraulic fluid is the life blood of the system, it transmits pressure and energy, seals close tolerance parts against leakage, minimizes wear and friction, remove heat and contaminates, and protects surfaces against rusting.

- Periodic fluid analysis is highly recommended to determine fluid life and predict possible problems.

- Filters must be checked and maintained to keep the fluid clean.

- Recommend filtering the fluid as it is being added to the system.

Fluid Change out recommendations:

- Drain the system while the fluid is hot to keep contaminates in suspension.

- Empty fluid from lines, cylinders, and actuators that may not drain properly.

- Siphon, pump or mop out any oil remaining in the reservoir.

- Wipe the reservoir clean, remove any contaminates, rust, or loose paint.

- Replace or clean filter elements, strainers, and filter housings.

- Refill system with new fluid, be sure to vent high points.

- Restart and check system for proper operation.

Caution:

Remember these are pressurized systems, you must shut the system down and release any pressure prior to opening the system or doing any repairs.

Source: SWEPCO®

Care and Maintenance of Hydraulic Systems:

If you want your systems maintained, cleaned, serviced, contact us for any assistance regarding care and maintenance of your Hydraulic Systems. Also for an independent oil analysis program of your current oil, we can take care of this for you.